Metal Roofing Gauges: What's Best Gauge For Residential?

You’ve explored your options for a new roof and you’re interested in the benefits of a metal roof. Now you have different options for gauges, colors and panel types and it’s a bit overwhelming. At Western States Metal Roofing we can help you figure out the answers to your questions, starting right here with gauges.

Keep in mind though that before you choose your metal roofing thickness, you must first decide on the type of metal roofing panel and the type of paint finish. We will discuss the following factors that will influence this decision and help you choose the correct gauge for your metal roof.

- Choose the correct metal roofing panel

- Types of paint systems

- Which gauge is best for a metal roof over a solid wood substrate

- Which gauge is best for a metal roofing that will be installed over metal purlins

- Comparing the different gauges for both applications

What's The Best Gauge For Metal Roofing?

Our goal in this article is to explain when a heavier or lighter gauge makes sense. Choosing the correct gauge of metal roofing can be very confusing. The higher the number of the gauge, the thinner the thickness of the metal roofing. For example, 29 gauge is thinner than 26 gauge and 24 gauge is heavier than 26 gauge. Then it gets even more complicated because different metals have different measuring standards. The thickness of copper is different than for steel.

The most common gauges for metal roofing are 29, 26, 24, and 22 gauge. The vast majority of what we sell is either 26 gauge metal roofing or 24 gauge metal roofing. Low end agricultural jobs are normally 26 gauge or 29 gauge. While a beautiful new home with a standing seam roof would likely be 24 gauge. If that same home is done with an exposed fastener panel it would likely be 29, 26, or 24 gauge.

The Type Of Metal Roofing Panels Affects Which Gauges Are Available

Before you pick the gauge of your metal roofing you must first decide on the type of metal roofing panel. You must answer these two basic questions:

- Do you want an exposed fastener metal roofing panel?

- Will you be purchasing standing seam metal roofing?

Exposed Fastener Panels

Exposed fastener panels such as ⅞” Corrugated, PBR panel, and 7.2 panel cost significantly less than a concealed fastener panel such as standing seam? Standing seam metal roofing will cost twice as much as corrugated metal roofing.

26 Gauge Corrugated Metal Roofing

If you want an inexpensive metal roofing panel then standing seam is not the best option for you. The best value will be a 26 gauge exposed fastener panel in a SMP paint finish. Keep in mind though that an exposed fastener panel means that you will have thousands of screws that will penetrate the panel. Each screw is a potential leak point at a later date.

A corrugated panel will cost $1.00-$1.25 per square foot in a 26 gauge SMP paint finish.

If you would like to learn more about exposed fastener and concealed fastener panels, we suggest reading or watching: Exposed Fastener Metal Panels v. Standing Seam Systems For Metal Roofs

24 Gauge Standing Seam Metal Roofing

Standing seam is the best metal roofing system. The main advantage of this panel is that the fasteners are concealed making it the most weathertight roofing panel. However, it is also the most expensive option and it will only be available in 24 gauge or heavier. It’s also accompanied by an expensive PVDF paint finish.

Standing seam metal roofing will cost $2.50-$3.50 per square foot in a 24 gauge PVDF paint finish.

If you choose a standing seam roof, you will nearly certainly be purchasing 24 gauge steel. However, if you have an exposed fastener panel you will have more flexibility to choose 29, 26, or 24 gauge roof metal.

The Type Of Paint System Affects Which Gauges Are Available

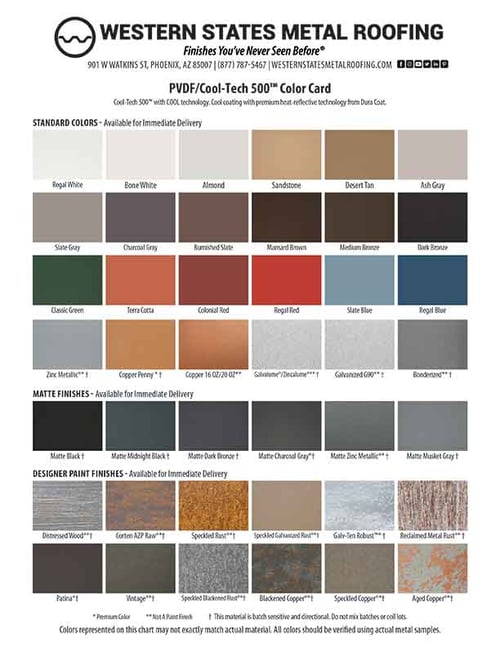

There are two choices when you are choosing a paint system

- PVDF paint

- Silicone-modified polyester which is referred to as SMP.

The easiest way to describe these paint finishes is the model of good, better, or best. PVDF would be considered “ best “ and SMP would be “ better. PVDF is the best paint finish that is available, but that does not mean that it is better for every roof.

Roof Metal Gauge For SMP Paint

SMP paint costs less than PVDF and is an excellent paint finish. This type of paint system is used more often for an agricultural application or for metal siding.

The single biggest disadvantage of SMP paint is that it will not hold the color integrity as long as a PVDF paint system.

SMP paint colors are typically light or neutral. You will rarely see metallic or bright and vibrant colors in SMP paint. When a light color fades over time it is much less noticeable than when a bright color fades. This is the primary reason that you will have less color choices and those colors will be light or earth tones primarily.

Metal roofing with a SMP paint finish will be available in 26 gauge roof metal primarily. However, it would not be uncommon to find SMP colors in 24 gauge or 29 gauge.

Gauge Of Metal Roofing With A PVDF Coating

PVDF is the best paint finish and it is not available in light gauge steel. If you want a PVDF paint finish you will nearly certainly be purchasing 24 gauge steel. You will have a greater selection of colors including bright and vibrant colors, matte finishes, and designer paint finishes.

The single biggest advantage PVDF has when compared to SMP paint is that it will hold the color integrity longer. PVDF paint systems will fade less when compared to an SMP paint system.

If you would like to learn more about SMP and PVDF paint systems then we suggest that you read: Best Paint System For My Metal Roof Panels: SMP v. PVDF

If you decide to use a PVDF paint system then you cannot purchase a light gauge steel. You will have to purchase a minimum of 24 gauge steel. Bright colors should only be purchased in PVDF.

Metal Roofing Gauge Thickness For Panels That Will Be Installed Over A Solid Wood Substrate?

When a metal roofing panel is installed over a wood substrate the strength of the panel becomes less of an issue. It does not have to span from support to support. Most metal roofing that attaches to a wood substrate is 29, 26, or 24 gauge.

26 Gauge Metal Roofing vs. 29 Gauge Metal Roofing

Although 29 gauge could be appropriate, we don’t recommend it. If you go this route, you are buying a flimsy panel that can be damaged more easily during a hail storm, has lesser snow loads, and has lesser wind uplift values. Furthermore, if you have long panel lengths you run a greater risk of damaging the panels due to expansion and contraction.

If you live in an area with high winds or snow then 29 gauge is not recommended. You are taking all of these risks and only saving a minimal amount of money. The cost difference between 26 gauge and 29 gauge is only 10-20% for the material cost only.

When you look at the overall installed cost of a metal roof the cost savings are almost nothing. A typical 25 square metal roof will cost between 10K and 20K installed, but the cost savings of using 29 gauge instead of 26 gauge is only $500-$1,000. We believe it’s a bad investment and for that reason we do not sell 29 gauge.

24 Gauge Metal Roofing vs. 26 Gauge Metal Roofing

When the metal roofing sits on a solid wood substrate a 26 gauge material is appropriate and a good value. However, there are instances in which a 24 gauge material would be a better choice. If you live in an area with high winds and a lot of snow than spending the additional money on 24 gauge would make sense. In addition, if you want a PVDF paint then you will nearly certainly need to purchase a 24 gauge steel.

Metal roofing in a 24 gauge steel will weigh approximately thirty percent more than 26 gauge steel. As a result there is normally about a thirty percent price difference. That price difference will be even greater if you choose both 24 gauge and PVDF paint. An average size roof of 25 squares will cost between 10K and 20K installed, but the cost savings of using 26 gauge instead of 24 gauge is only $1,000-1,500.

If you are installing an exposed fastener panel then you will normally have a lot of options. You can choose 24 gauge in PVDF or numerous gauges in SMP paint systems. If you are installing standing seam panels then you are limited to 24 gauge PVDF.

This is not a simple decision as both gauges will work in most applications. If you have lots of snow, high winds, or want a PVDF paint finish then spend the extra money and purchase 24 gauge steel. However, if saving money is the main priority and you like the SMP colors, then a 26 gauge steel would make sense provided you do not get high winds or snow on your roof. Metal roofing in 26 gauge is still a quality product at an excellent price point.

Metal Roofing Gauge Thickness For Panels That Will Be Installed Over Metal Purlins?

When a metal roofing panel is installed over metal purlins the strength of the panel becomes extremely important. The metal roofing panels need to be able to span the distance between the purlins and also handle the load and wind uplift. There are load charts and uplift charts available online that will show you the capabilities of the panels.

Each panel profile will have different engineering values. For example, the load chart for ⅞” corrugated is different than the load chart for a PBR panel. It is recommended that you have an engineer determine the appropriate span between metal purlins and the gauge of metal that will be used.

What Metal Roofing Thickness Is Best For Panels That Will Be Spanning From Purlin To Purlin?

This conversation starts with the gauge you should NOT use. Metal roofing in 29 gauge is just too flimsy to be used in this application. The appropriate gauge ranges from as light as 26 gauge to as heavy as 20 gauge. The further the metal roofing has to span between each support than the heavier the gauge needs to be.

When you have a short span of four feet or less, a lighter gauge such as 26 gauge may be appropriate. If the span is between four and six feet, a 24 gauge is appropriate. For spans longer than six feet, a heavier gauge steel (22 gauge or thicker) is likely required. Every job is different and there are different requirements for uplift and load capabilities. Therefore, always consult an engineer to come up with the panel type, panel gauge, and the appropriate distance between metal purlins.

When you are comparing different bids from metal roofing contractors it is important to pay close attention to the gauge of steel that will be supplied. A metal roof that is manufactured from a heavier gauge steel will be stronger, handle foot traffic better, have additional wind resistance, and will be a longer lasting product.

Steps To Choosing A Perfect Metal Roof

As you go through the process of choosing a metal roof for your home the first step is determining the panel type. Here is an article that will help you with that: Exposed Fastener Metal Panels v. Standing Seam Systems For Metal Roofs

Secondly, you have to determine the gauge of the steel. This article should give you a good idea of what gauge you should consider for your home.

The next step is to determine the type of paint system and the color of your metal roof. This article will help you with that decision: Metal Roofing Colors: 5 Tips To Pick The Best Metal Roofing Color

About Paul Rubio

Paul Rubio is the Vice President and one of the owners of Western States Metal Roofing. He has been in the metal roofing industry for 25 years. WSMR is a manufacturer of metal roofing, wall panels, and metal siding. We have colors and finishes that nobody else has with nearly 100 different colors in stock. Our selection of color options and finishes is likely the largest in the industry.