What Gauge Metal Roofing Should I Use? (26 Gauge v. 29 Gauge)

What Is A Roof Gauge?

Gauge refers to the thickness of the metal panel and is represented in number form. Most metal roof and metal siding panels on the market are between 20- 29 gauge, with 20-gauge being the thickest and 29-gauge being the thinnest panels sold. These numbers refer to the decimal thickness of the steel and they have a range. For Example, 26 gauge could be a steel as light as .0179 or as heavy as .0217.

26 Gauge Vs 29 Gauge Metal Roofing

While 26 gauge and 24 gauge are generally the standard for most commercial and residential installations, some choose to work with 29-gauge because it is more affordable. But is the savings worth working with a thinner, less durable material? Is a 29 gauge metal roof good?

In this article, we analyze which panel provides the most value by comparing 26 gauge vs 29 gauge steel in the following areas:

- Durability

- Appearance

- Cost

1. Durability Of 26 Gauge Vs. 29 Gauge Roofing

Panels in both size gauges provide the durability benefits of metal. They are fire-resistant, low maintenance, and protect against corrosion. However, the thickness of a panel does make a difference in its durability.

Remember, when it comes to gauge: the higher the number, the thinner the material. This is why 29-gauge is thinner than 26-gauge. Since the product is thinner, it’s not as strong as 26-gauge. When it comes to harsh weather elements like snow, high winds or hail, a thinner material could become a problem.

If a structure is located in a climate that has snowfall regularly, 29-gauge is not recommended. The weight of the snow could be too much for the roof to handle, resulting in leaks or even causing the roof to cave in.

Homeowners in areas that experience high winds also want to stay away from thinner metal. A 26-gauge roof is not only thicker but also heavier than 29-gauge. The added weight gives the roof a greater chance of staying intact in the event of a very heavy wind storm.

26 gauge will out-perform any 29 gauge material. In hail prone areas, a heavier gauge will make sense due to impact-resistance. If you live in an area that experiences hail often, then an even thicker gauge is a better option for your climate. Heavier material, such as 24-gauge or even 22-gauge, is more suitable for any area that is prone to extreme weather conditions.

To discover the differences between 24 gauge and 26 gauge roofing, we recommend reading:

What Gauge Metal Roofing Is Best? 24 Gauge vs. 26 Gauge

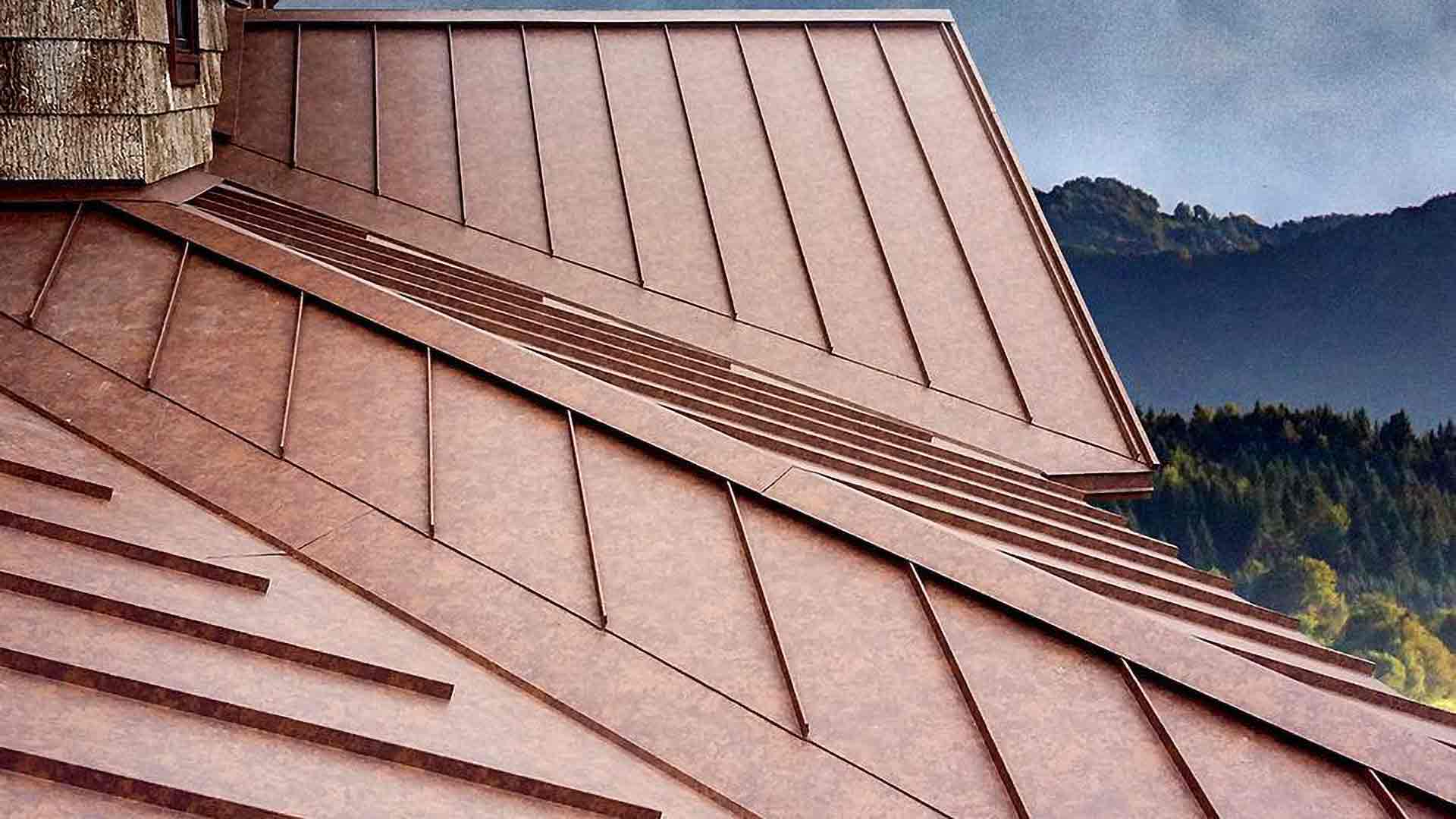

2. Appearance

While there isn’t a noticeable difference in appearance between the panel gauges, the differing compositions of the panels could lead to some aesthetic changes.

When it comes to installation, simple errors can ultimately compromise the roof’s appearance. If screws are over-tightened, bumps and waves will form, known as oil canning . The appearance of a 29-gauge roof is usually more affected by this than 26-gauge because thinner panels make these mistakes appear more obvious.

3. Cost Difference Between 26-Gauge And 29-Gauge

As a panel gets thicker, it also gets more expensive. The cost of a 26-gauge product will be about 10 to 15 percent higher than 29-gauge. The cost of repairs down the line could be far greater than the initial savings from purchasing products with a higher gauge. While we certainly understand that every dollar matters, you have to consider if the relatively small savings is worth the risk of using less durable panels.

For example, a 25 sq. ft. roof will cost you between $15,000-$20,000, and you would only save about $1,000 by using 29-gauge panels instead of 26-gauge.

When Should I Use 26 Gauge Metal Vs 29-Gauge?

Thicker panels are more expensive and are not a necessity for every type of structure. You have to take factors such as climate, building structure, and budget into consideration to determine which gauge is the best choice for your project.

Below are some general guidelines on when it’s best to use each panel:

You Should Use 26 Gauge Metal Panels If:

-

- The panels are being installed in a climate with extreme weather conditions (hail, strong winds, heavy snow).

- Longevity is a top priority and you want panels that will last longer.

- Appearance is a top priority and you want a product with greater resistance to dents.

- You are building an open frame structure, such as a pole barn. While 29-gauge can be used for the walls of small barns, 26-gauge is advised for the roof and walls of larger barns.

You Should Use 29 Gauge Metal Panels If:

-

- Cost is a top priority and you want the most affordable product.

- You are not using the structure long term and therefore are not concerned with its lifespan.

- You are using the panels for a roof located in a mild climate that does not experience snow, hail, or storm conditions often.

Metal Roofing Panel Profile And Metal Gauge

As we mentioned at the beginning of the article, there are multiple decisions to make when picking out your metal panels. Besides gauge, you also have to decide which type of panel to use, such as: ⅞” Corrugated, R-Panel, 7.2 panel, or standing seam.

These decisions sometimes go hand in hand, as not every panel is available in every gauge. For example, if you are planning on installing a standing seam roof, you will have to go with a thicker gauge as these panels usually only come in 22 to 24 gauge. However, a corrugated metal roof comes a wider range of gauges.

At Western States Metal Roofing, we manufacture metal panels ranging from 20 to 26 gauge. We supply roofing and siding for residential and commercial buildings in all different types of climates and understand that some areas have conditions that require a certain gauge. If you need assistance deciding which gauge is best for your project, our knowledgeable team is here to help.

Let Us Help You Choose A Metal Roofing Color

Now that you have a better idea of what gauge you should use it’s time to take the next step and choose a metal roofing color. We have written an easy to read color selection guide.

If you would like an even more detailed article on choosing a color we recommend this article: Metal Roofing Colors: 5 Tips To Pick The Best Metal Roofing Color

Buy Manufacturer Direct And Save Money On Your Metal Roofing Panels

We recommend that you get a quote from more than one company. You want a company that has great google reviews and a fair price. Our online form is quick and easy to fill out. Let us provide you a free quote.

When you buy metal roofing from Western States Metal Roofing you are purchasing directly from the manufacturer. Buying directly from the metal supplier can save you 15% to 50%. Our company offers inexpensive delivery throughout the entire country. Give us a chance to earn your trust and provide excellent customer service. Look at out our google reviews and give us a call at 877-787-5467.

Start the process of picking out your panels by requesting a quote.