Synthetic vs. Felt Roof Underlayment: Which Should I Use?

When it comes to roof underlayment, the phrase "out of sight, out of mind" seems fitting. Since underlayment is not visible after the roof installation, it's often overlooked. Some customers question if it's even necessary. Even though it cannot be seen, underlayment is an incredibly important component to a roof that has a major impact on its longevity. How well roof underlayment performs will depend on which type you use.

At Western States Metal Roofing, we have been in the roofing industry for over 20 years and have encountered every type of scenario with both types of underlayment. We generally prefer the use of synthetic underlay, as it is more durable and will last longer. However, there are times when it will make more sense for a roofing contractor to use felt underlayment for a roofing system as it is more economical. In some cases, felt may even be required to stay within the building code requirements.

In this article, we will compare synthetic vs. felt underlayment in the following areas:

- Weight

- Cost

- Performance

- Longevity

But first, let's discuss why roofing underlayment is so important.

What Is Roof Underlayment?

Roofing underlayment is a water-resistant barrier that serves as an extra layer of protection from the elements. It is installed directly onto the roof deck , underneath the rest of the roof system.

Roofing underlayment has many advantages which include:

- Serving as added insulation from wind to keep your home from being drafty.

- Acting as a noise barrier from rain or other elements hitting the roof.

- Providing an even surface to lay roofing material over so your roof looks uniform.

- Keeping you in compliance with your roofing material warranty (if applicable).

- Protecting your home from water and debris in the event that part of your roofing is damaged or comes off during a storm.

Now that you can see how valuable underlayment is, let's discuss how the two types of underlayment compare with each other.

How Much Does Roof Underlayment Weigh?

As the weight of underlayment increases, so does it's thickness. When underlayment is lighter and thinner, it provides more square coverage per roll.

While felt is weighed by pounds per roofing square (100 square feet), synthetics are rated by grams per square meter (GSM).

Weight Of Felt Underlayment

- #15 Felt: Weighs 7.5 to 12.5 pounds per roofing square

- #30 Felt: Weighs 16 to 27 pounds per roofing square

Weight Of Synthetic Underlayment

- Anywhere from 40-100 Grams per Square Meter

Conclusion

Roofing felt requires more weight than synthetic underlayment to cover the same area. It would take 86.5 pounds of felt to cover the same area as roughly a 22-pound single roll of synthetic underlayment. Winner: synthetic

Roof Underlayment Cost

Roofing felt is more affordable than synthetic underlayment. The price difference is mostly due to the components of each underlayment, as the fiberglass in synthetic underlayment gives it superior resistance to tearing and increased stability as opposed to felt. We will go into more detail on the make-up of each underlayment in the next section.

Felt Underlayment Cost

- #15 felt: 5 cents per square foot

- #30 felt: 10 cents per square foot

Synthetic Underlayment Cost

- Synthetic underlayment costs 17 cents to 25 cents per square foot.

- Felt is the more economical option of the two underlayment. Winner: felt

What Is Roof Underlayment Made Of?

The performance of underlayment is directly associated with the quality of its components.

Felt Underlayment For Roofing

Roofing felt is made from recycled corrugated paper mixed with sawdust. The paper is mixed with asphalt for increased water resistance. When compared to synthetic underlayment, felt is more resistant to leaking at staple or nail penetrations.

As mentioned earlier, felt comes in two different weights. #30 provides better protection than #15 because it is thicker and more resistant to potential damage.

Synthetic Underlayment For Roofing

Synthetic material is made from sheet products made of laminated polypropylene or polyethylene plastic. Synthetic products have excellent tear resistance and will not tear and break from screws and nails penetrating it.

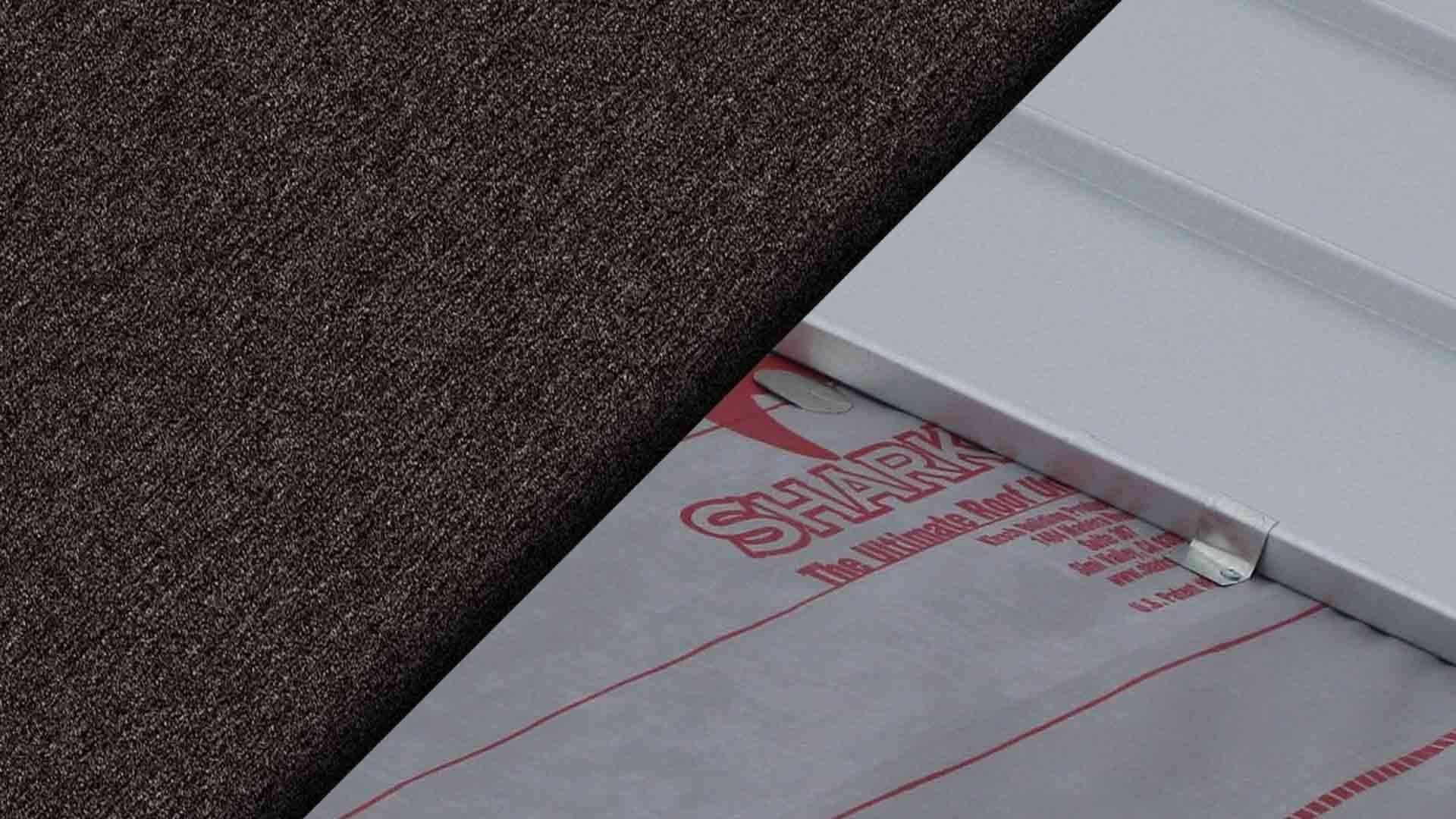

Learn about the different types of Sharkskin synthetic underlayment by clicking on the banner below:

How Long Can Roof Underlayment Be Left Exposed?

The durability of synthetic underlayment makes it perfect for use on a roof that is not going to be installed immediately as material will not be harmed from exposure to weather conditions. Depending on the underlayment, it can remain exposed anywhere from 2 months up to 30 months and will still remain watertight. Since the material doesn't absorb moisture, it keeps from wrinkling which would ultimately compromise the finished look of the roof.

Synthetic underlayment also provides better traction for roofers than roofing felt in both wet and dry conditions, making it a safer product to work with during installation.

By offering tear resistance, protection from the elements, and a safer surface area to walk on, synthetic underlayment outperforms felt underlayment. Winner: synthetic

How Long Does Roof Underlayment Last?

Felt Underlayment

You can expect felt underlayment to generally last anywhere from 12 to 20 years .

Synthetic Underlayment

Synthetic material can last anywhere from 25 to 40 years , depending on the manufacturer.

A roof is more prone to leaks once its protective underlayment starts to break down. This makes picking the underlayment with the greatest longevity important in order to minimize future maintenance and maximize the lifespan of your roof.

Synthetic underlayment is expected to last longer than felt underlayment. However, both types of underlayment should be inspected every 3-5 years or sooner if you suspect a problem. Winner: synthetic

Types Of Roofing Underlayment

For hundreds of years, felt was the go-to material to use for roofing underlayment. It was only within the last twenty years that synthetic underlayment was introduced as an improved product that would not have the shortcomings of felt. Still, felt is an effective underlayment and sometimes might be the better choice for a project.

What Roof Underlayment Should I Use?

Felt underlayment is recommended when:

- Cost is the main concern. Felt is the more affordable underlayment solution.

- Building code requires the use of felt underlayment.

Synthetic underlayment is recommended when you are looking for:

- Underlayment that will last the longest.

- Easy installation. This material is lightweight and safer to walk on than felt.

- Smoother appearance from laying flatter on the roof decking.

- Resistance to mold and mildew.

- Durability. Synthetic underlayment can withstand exposure to the elements for weeks or even months.

At Western States Metal Roofing, we have been in the roofing manufacturing industry for over 20 years. We understand how important using quality products is to having a successful roof installation and we take pride in the products we offer.

Choosing the right underlayment for your roof can be confusing. Our team is happy to answer any questions you have. We have roofing underlayment ready to be shipped immediately in addition to all of our other roofing products and accessories. We can also provide you with a free quote for any of our products.

If you are researching underlayment for a metal roof then these two videos will be helpful: